03

2025

-

04

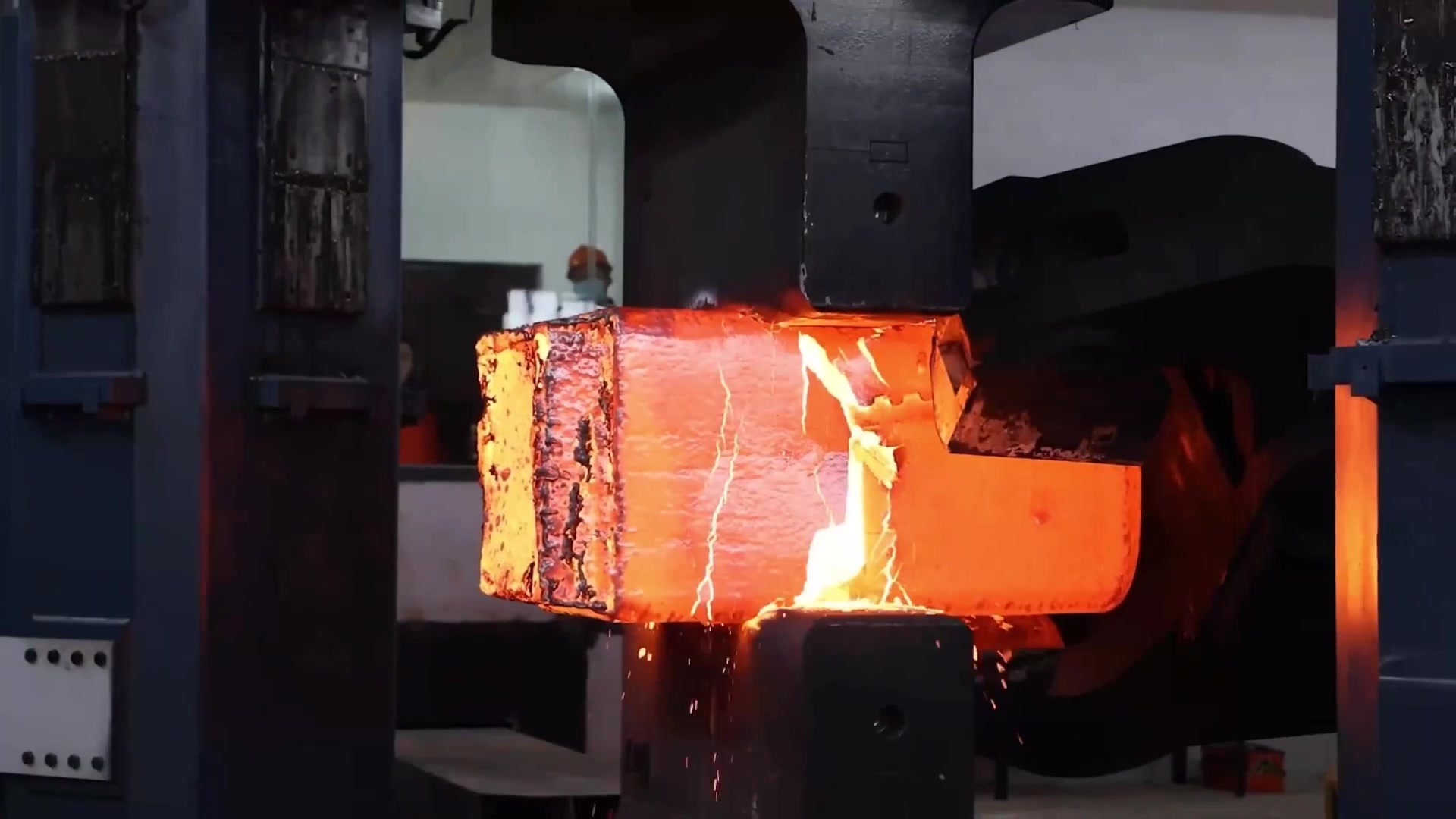

What are the functions of the spindle forging?

The spindle forging is a key component in power transmission. In the manufacturing processes of machine tools, automobiles, ships, etc., the spindle needs to transmit power from the engine or other power sources to drive cutting tools, transmission wheels, and other components to work.

Spindle forgings play a crucial role in mechanical engineering, with their primary functions encompassing the following aspects:

I. Support Function

One of the main functions of spindle forgings is to act as a support for mechanical devices. During the operation of mechanical equipment, the spindle is subjected to various forces, including rotational forces and cutting forces. Therefore, it must possess sufficient strength and stability to ensure that the equipment maintains accuracy and stability during long-term operation.

II. Power Transmission

Spindle forgings are also key components in power transmission. In the manufacturing processes of machine tools, automobiles, ships, etc., the spindle needs to transmit power from the engine or other power sources to drive cutting tools, transmission wheels, and other components. Therefore, spindle forgings must have efficient transmission performance to ensure smooth power transmission.

III. Improving Machining Accuracy

The quality and precision of spindle forgings directly affect the machining accuracy of mechanical equipment. High-precision spindles can ensure the stable operation and machining accuracy of mechanical equipment, thereby improving product quality and production efficiency. Therefore, very high requirements are placed on the manufacturing and processing of spindle forgings.

IV. Withstanding Heavy Loads and Impacts

In the fields of heavy machinery and engineering machinery, spindle forgings need to withstand heavy loads and impacts. Therefore, they must have excellent strength and toughness to cope with various harsh working environments.

V. Improving Equipment Lifespan

High-quality spindle forgings can improve the lifespan of mechanical equipment. By using high-strength, high-wear-resistant materials and precise manufacturing processes, spindle forgings with a long lifespan can be manufactured, thereby reducing equipment maintenance costs and downtime.

VI. Other Functions

In addition, spindle forgings also have other functions. For example, they can act as heat exchangers to help mechanical equipment dissipate heat; they can also serve as a medium for storing energy, providing additional power when the equipment starts up.

In summary, spindle forgings in mechanical engineering have multiple functions, including support, power transmission, improved machining accuracy, withstanding heavy loads and impacts, and extending equipment lifespan. Due to their important role and complex manufacturing processes, very high requirements are placed on the quality and precision of spindle forgings.

Jinbo Forging Dingxiang Flange

Related information

2025-04-03

Introduction to flange pipe plate, come and collect it!

Flange plates, as important connecting pieces, are widely used in various piping systems.

2025-04-03

Manufacturing process of spindle forging

Spindle forgings are one of the key components in mechanical equipment, and their manufacturing process requires strict procedures to ensure quality.

2025-04-03

Types and Applications of Flanges

A flange is a connecting device widely used in the connection of various pipes, containers, valves, and other equipment.

2025-04-03

Working principle of carbon steel flanges

Carbon steel flanges are connecting devices widely used in piping systems and other industrial fields. Their working principle is based on mechanical connection and sealing principles, ensuring efficient and safe system operation.

2025-04-03

What improvements should be made in the production process of forgings?

The production process of forgings is a complex process involving multiple stages. To ensure product quality and production efficiency, a series of improvements are necessary.

2025-04-03

What is the cold bending process flow?

Cold bending is a metal sheet bending process widely used in construction, machinery, transportation and other fields.