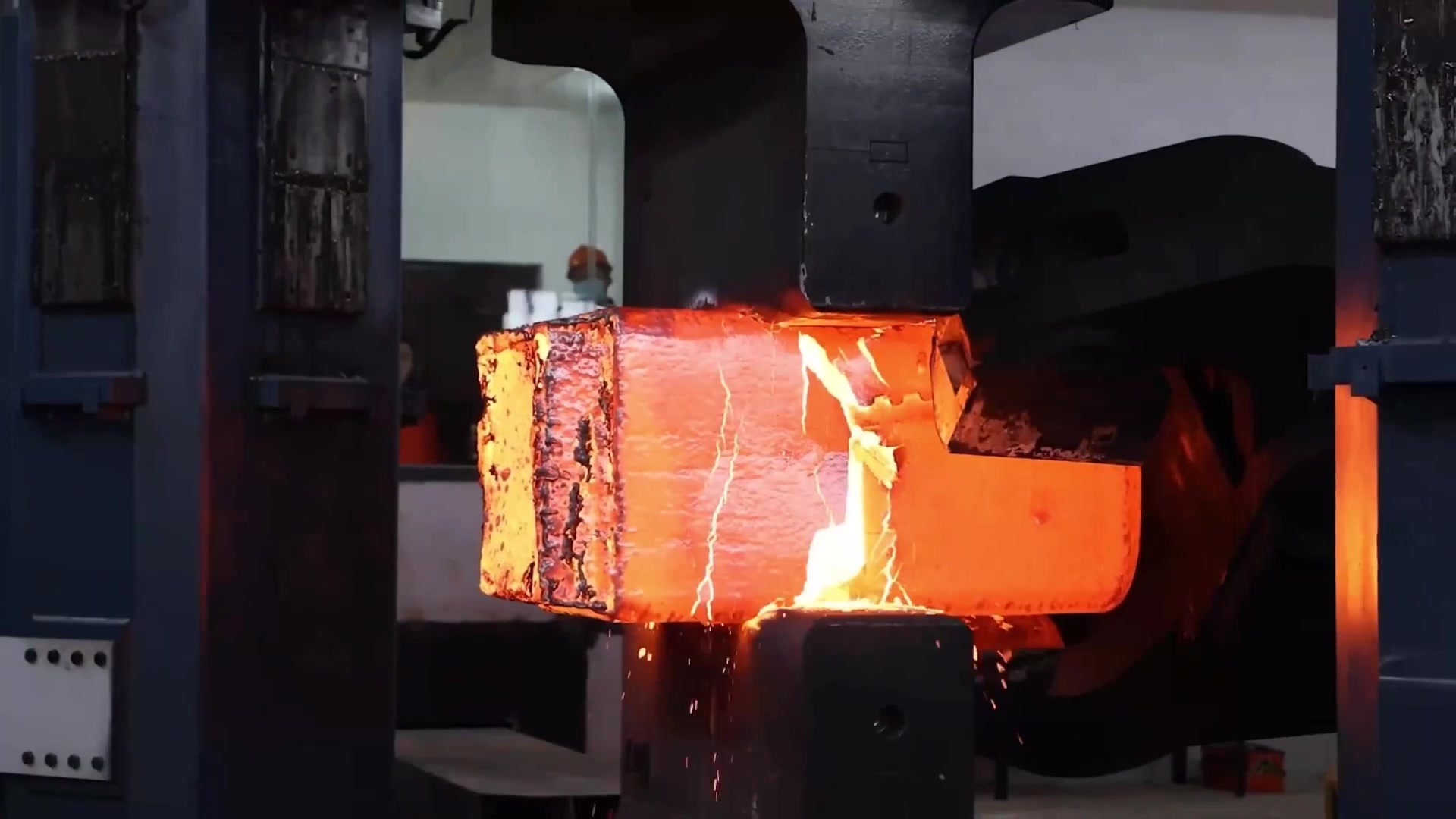

QUALITY

Quality System

1. Strictly follow the requirements of IS09001:2015 standard and implement the company's quality system and various regulations of documents;

2. In the manufacturing process of products, independent production mode can be implemented, and the "Quality Assurance Outline" can be jointly formulated with customers;

3. Raw material procurement shall be selected from the company's certified suppliers. When exceeding the scope, the certification procedure must be initiated before supplementary suppliers are added.

4. All incoming raw materials must be re-inspected, and raw materials that do not meet the production requirements are absolutely not allowed to enter the production process;

5. Strictly implement the factory's "Inspection Specifications" during the production process, and implement the "three inspections" system for semi-finished products;

6. Carefully keep the quality records and fill in the "Process Transfer Card" during the production process to ensure the traceability of products;

7. The technical department ensures the accuracy of measuring instruments; the equipment management department ensures the integrity of equipment, and the tooling meets the process requirements;

8. Before the finished products are put into storage, final inspection shall be carried out according to relevant standards and specifications to ensure that the qualified rate is 100%;

9. Carefully label.

Brinell hardness tester

Mechanical Properties

Test Items:

Room temperature tensile test of metallic materials, Charpy impact test of metallic materials, hardness test of metallic materials.

Testing Equipment:

WDW-300E Microcomputer Controlled Electronic Universal Testing Machine

JB-300B Impact Tester

CTS-50 impact test notch projector, CSL-B electric double-blade lathe

HB3000B Brinell Hardness Tester / SW-6230 Shen Da Wei Rockwell Hardness Tester

Chemical Composition Analysis

Test Items:

Rapid detection of chemical composition of metallic materials

Testing Equipment:

SparkCCD6500 /

Niton XLT898 handheld analyzer.

Metallographic Analysis

Test Items:

High and low magnification detection of metallic materials, mainly acid etching test, detection and evaluation of non-metallic inclusions, detection and evaluation of average grain size of metals.

Test Items:

MP-2 metallographic polishing machine

4XC metallographic microscope.

Non-destructive Testing

Test Items:

High and low magnification detection of metallic materials, mainly acid etching test, detection and evaluation of non-metallic inclusions, detection and evaluation of average grain size of metals.

Testing Equipment:

Youlian PXUT-300 digital flaw detector, CDX-111 multi-purpose magnetic powder flaw detector.