03

2025

-

04

What are the commonly used materials and properties of shaft forgings?

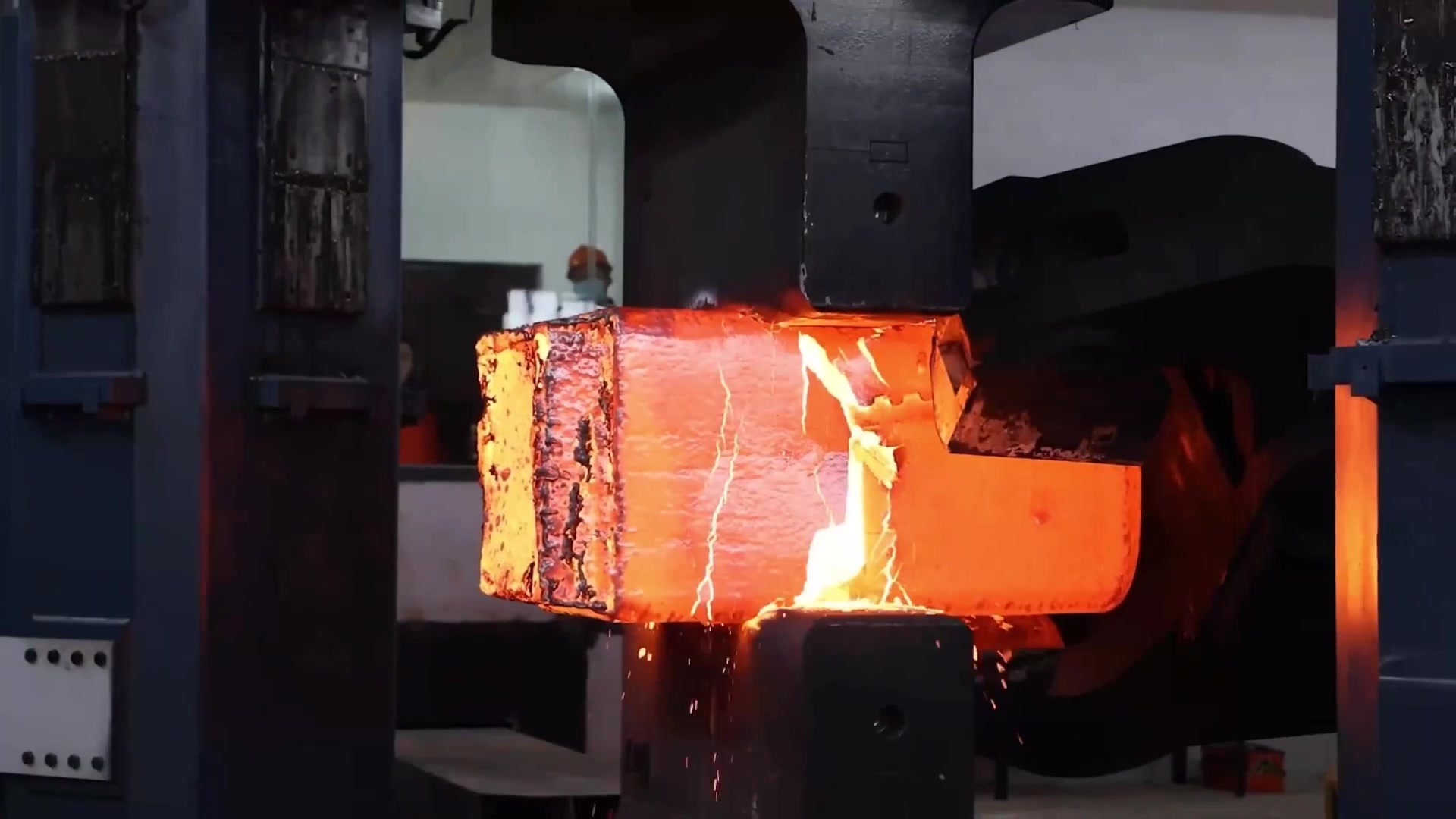

Shaft forgings are important components in mechanical manufacturing and are widely used in various mechanical equipment.

Shaft forgings are important components in mechanical manufacturing and are widely used in various mechanical equipment. Their material and performance directly affect the efficiency and safety of the equipment. The following is an introduction to the commonly used materials and properties of shaft forgings:

I. Commonly Used Materials

1. Carbon Steel

Carbon steel is one of the most commonly used materials for shaft forgings. It has high strength and good toughness, and its cost is relatively low.

2. Alloy Steel

Alloy steel has higher strength and wear resistance, suitable for high-strength, high-load shaft forgings.

3. Stainless Steel

Stainless steel has good corrosion resistance and oxidation resistance, suitable for applications in humid and corrosive environments.

4. Titanium Alloy

Titanium alloy has light weight, high strength, good corrosion resistance and high temperature performance, suitable for shaft forgings in special environments.

II. Performance Characteristics

1. Strength

Shaft forgings need to have high strength to withstand various loads during equipment operation.

2. Toughness

Shaft forgings need to have good toughness to absorb impact and vibration, ensuring stable equipment operation.

3. Wear Resistance

Friction occurs during the operation of shaft forgings, so good wear resistance is required to extend the service life.

4. Fatigue Strength

Shaft forgings work under alternating loads and need to have high fatigue strength to prevent fatigue fracture.

5. Corrosion Resistance and Oxidation Resistance

Shaft forgings used in special environments need to have corrosion resistance and oxidation resistance to resist the erosion of harsh environments on the material.

6. Other Properties

Shaft forgings also need to have good machinability, weldability, and heat treatment properties for subsequent processing and assembly.

In summary, the selection of materials and properties of shaft forgings should be based on the specific application scenario and requirements. When selecting materials, factors such as strength, toughness, wear resistance, fatigue strength, corrosion resistance, and oxidation resistance should be considered comprehensively. At the same time, the processability and cost of the material should also be considered. Ensure that the performance of the shaft forgings meets the design requirements of the equipment to ensure safe and efficient operation of the equipment.

Jinbo Forging Dingxiang Flange

Related information

2025-04-03

Introduction to flange pipe plate, come and collect it!

Flange plates, as important connecting pieces, are widely used in various piping systems.

2025-04-03

Manufacturing process of spindle forging

Spindle forgings are one of the key components in mechanical equipment, and their manufacturing process requires strict procedures to ensure quality.

2025-04-03

Types and Applications of Flanges

A flange is a connecting device widely used in the connection of various pipes, containers, valves, and other equipment.

2025-04-03

Working principle of carbon steel flanges

Carbon steel flanges are connecting devices widely used in piping systems and other industrial fields. Their working principle is based on mechanical connection and sealing principles, ensuring efficient and safe system operation.

2025-04-03

What improvements should be made in the production process of forgings?

The production process of forgings is a complex process involving multiple stages. To ensure product quality and production efficiency, a series of improvements are necessary.

2025-04-03

What is the cold bending process flow?

Cold bending is a metal sheet bending process widely used in construction, machinery, transportation and other fields.