03

2025

-

04

Introduction to flange pipe plate, come and collect it!

Flange plates, as important connecting pieces, are widely used in various piping systems.

Introduction to the Uses of Flanged Pipe Plates

I. Introduction

As an important connecting component, flanged pipe plates are widely used in various pipeline systems. Their unique design and excellent performance make them an indispensable part of many industrial fields. This article will detail the uses of flanged pipe plates to help you better understand this product.

II. Connecting and Supporting Functions

One of the main functions of flanged pipe plates is to connect pipeline systems. During pipeline connection, flanged pipe plates ensure a firm connection between pipes, preventing media leakage. In addition, it also plays a supporting role, bearing the internal pressure and external load of the pipeline, ensuring the stable operation of the pipeline system.

III. Wide Range of Applications

1. Chemical Industry: In chemical production, flanged pipe plates are used to connect various equipment, such as reactors, heat exchangers, and storage tanks. Their excellent sealing performance and strength can withstand the corrosion of various corrosive media.

2. Petroleum Industry: In oil exploration and processing, flanged pipe plates are used to transport crude oil, natural gas, and other media, ensuring the reliability and safety of oil and gas transportation.

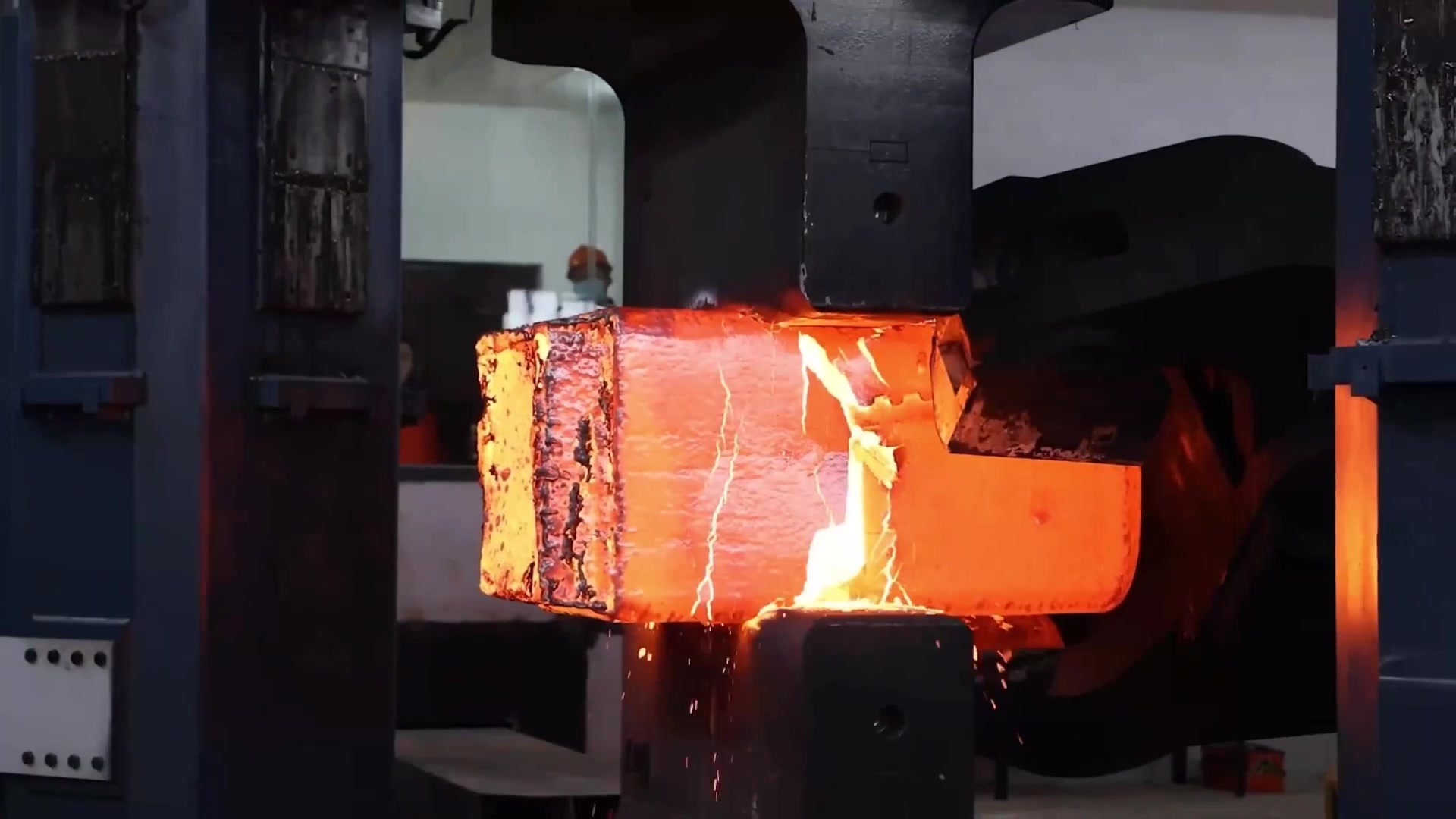

3. Metallurgical Industry: In metallurgical production, flanged pipe plates are used to connect various equipment and pipelines, such as blast furnaces, converters, and smelting equipment. Their high-temperature resistance performance can meet the needs of metallurgical production.

4. Power Industry: In power systems, flanged pipe plates are used to connect steam pipes, cooling water pipes, etc., ensuring the stable operation of the power system.

5. Other Fields: In addition, flanged pipe plates are also widely used in construction, pharmaceuticals, food, and other fields, providing reliable connection and support for various industries.

IV. Product Features and Advantages

Flanged pipe plates have the following characteristics and advantages:

1. Compact structure, easy installation;

2. Good sealing performance, preventing media leakage;

3. High pressure resistance, adaptable to various complex environments;

4. Diverse materials to meet the needs of different media and industries.

V. Conclusion

In summary, as an important connecting component, flanged pipe plates are widely used in the chemical, petroleum, metallurgical, and power industries. Their connecting and supporting functions provide important guarantees for the stable operation of pipeline systems. Hopefully, this introduction will help you better understand the uses of flanged pipe plates and provide you with a reference for selecting and using them in practical applications. Bookmark this for future reference!

Jinbo Forging Dingxiang Flange

Previous

Previous

Related information

2025-04-03

Introduction to flange pipe plate, come and collect it!

Flange plates, as important connecting pieces, are widely used in various piping systems.

2025-04-03

Manufacturing process of spindle forging

Spindle forgings are one of the key components in mechanical equipment, and their manufacturing process requires strict procedures to ensure quality.

2025-04-03

Types and Applications of Flanges

A flange is a connecting device widely used in the connection of various pipes, containers, valves, and other equipment.

2025-04-03

Working principle of carbon steel flanges

Carbon steel flanges are connecting devices widely used in piping systems and other industrial fields. Their working principle is based on mechanical connection and sealing principles, ensuring efficient and safe system operation.

2025-04-03

What improvements should be made in the production process of forgings?

The production process of forgings is a complex process involving multiple stages. To ensure product quality and production efficiency, a series of improvements are necessary.

2025-04-03

What is the cold bending process flow?

Cold bending is a metal sheet bending process widely used in construction, machinery, transportation and other fields.