03

2025

-

04

Tips for selecting large forging flange manufacturers?

Before selecting a manufacturer of large forged flanges, you must first clarify your needs and purchasing purpose.

Tips for Choosing Large Forged Flange Manufacturers

I. Understand Your Needs and Objectives

Before selecting a large forged flange manufacturer, you must first clarify your needs and purchasing objectives. Determine the basic parameters of the required flange, such as type, specifications, and material, to more accurately screen out manufacturers that meet your requirements.

II. Market Research

1. Collect Information: Understand the basic information of major flange manufacturers through industry friends, colleagues, or online channels.

2. Manufacturer Reputation: Check the manufacturer's history, qualifications, and reputation to ensure you choose a reputable manufacturer.

3. Product Comparison: Compare the product quality, price, and service of different manufacturers to screen out manufacturers with a high price-performance ratio.

III. On-site Inspection

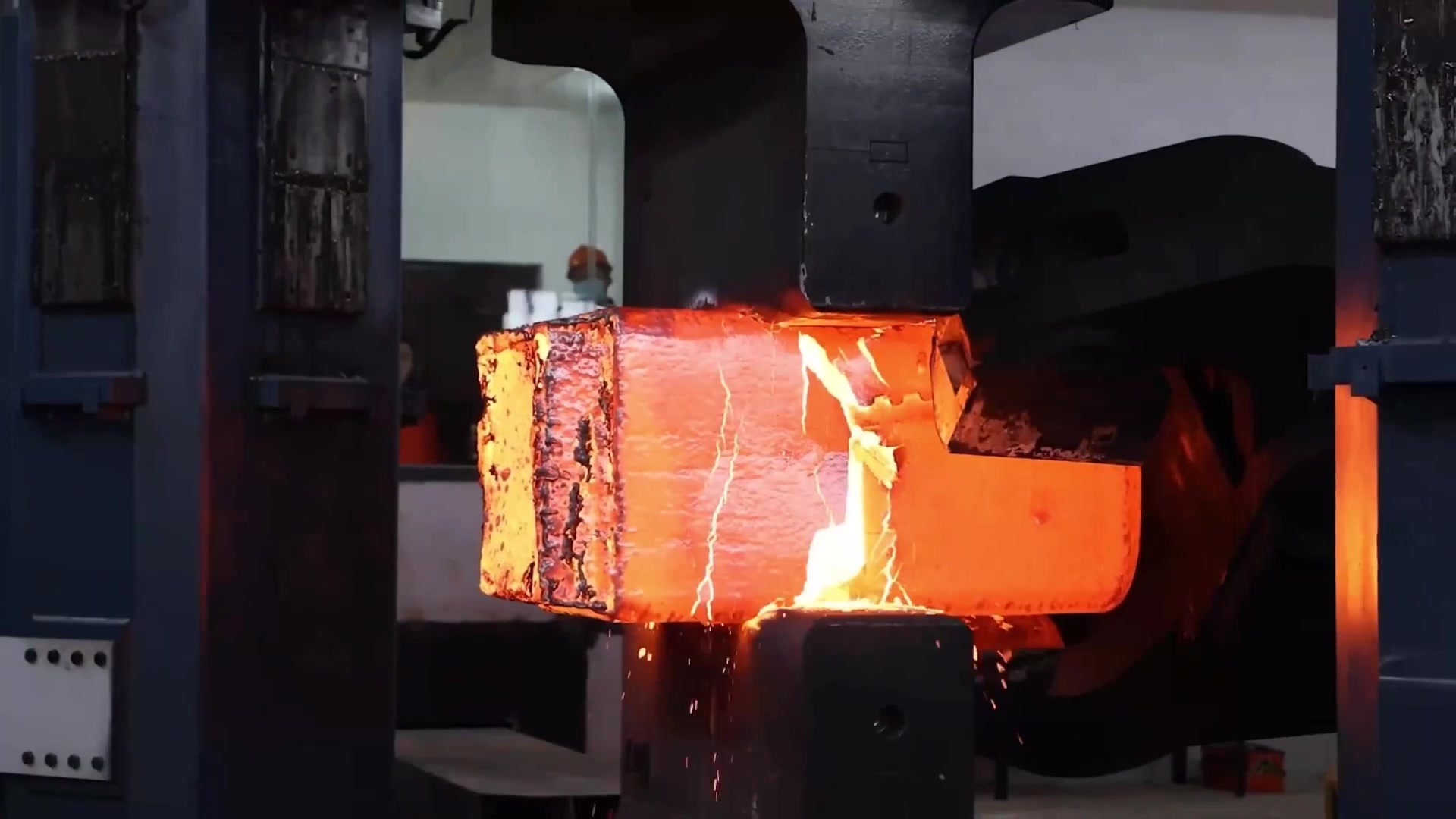

1. Factory Scale: Visit the manufacturer's production site to understand the production scale, equipment status, and production process.

2. Product Inspection: Check product samples to understand their quality, performance, and compliance standards.

3. Production Capacity: Evaluate the manufacturer's production capacity and delivery time to ensure that it can meet your needs.

IV. Communication and Negotiation

1. Inquire about Details: Communicate with the manufacturer in detail to understand the detailed specifications, price, and delivery time of the product.

2. Contract Terms: Ensure that the contract terms are clear to avoid future disputes.

3. After-sales Service: Understand the manufacturer's after-sales service policy to ensure that problems can be resolved promptly.

V. Attention to Detail

1. Qualification Certification: Ensure that the selected manufacturer has relevant qualification certifications, such as ISO9001.

2. Accumulated Experience: Choose a manufacturer with rich production experience that can better meet your needs.

3. Reasonable Price: Avoid only looking at the price; consider the quality and service of the product.

4. Contract Signing: Before signing the contract, carefully check the contract terms to ensure there are no errors.

VI. Summary and Decision

Based on the above steps, comprehensively evaluate each manufacturer and select the most suitable large forged flange manufacturer. Remember, choosing a manufacturer should not only consider the price but also the quality, service, and reputation.

In short, selecting a large forged flange manufacturer requires a full understanding of needs, market research, on-site inspections, communication and negotiation, and attention to detail. Only in this way can you choose a high-quality manufacturer with a high price-performance ratio to ensure that the purchased flanges meet requirements.

Jinbo Forging Dingxiang Flange

Related information

2025-04-03

Introduction to flange pipe plate, come and collect it!

Flange plates, as important connecting pieces, are widely used in various piping systems.

2025-04-03

Manufacturing process of spindle forging

Spindle forgings are one of the key components in mechanical equipment, and their manufacturing process requires strict procedures to ensure quality.

2025-04-03

Types and Applications of Flanges

A flange is a connecting device widely used in the connection of various pipes, containers, valves, and other equipment.

2025-04-03

Working principle of carbon steel flanges

Carbon steel flanges are connecting devices widely used in piping systems and other industrial fields. Their working principle is based on mechanical connection and sealing principles, ensuring efficient and safe system operation.

2025-04-03

What improvements should be made in the production process of forgings?

The production process of forgings is a complex process involving multiple stages. To ensure product quality and production efficiency, a series of improvements are necessary.

2025-04-03

What is the cold bending process flow?

Cold bending is a metal sheet bending process widely used in construction, machinery, transportation and other fields.