03

2025

-

04

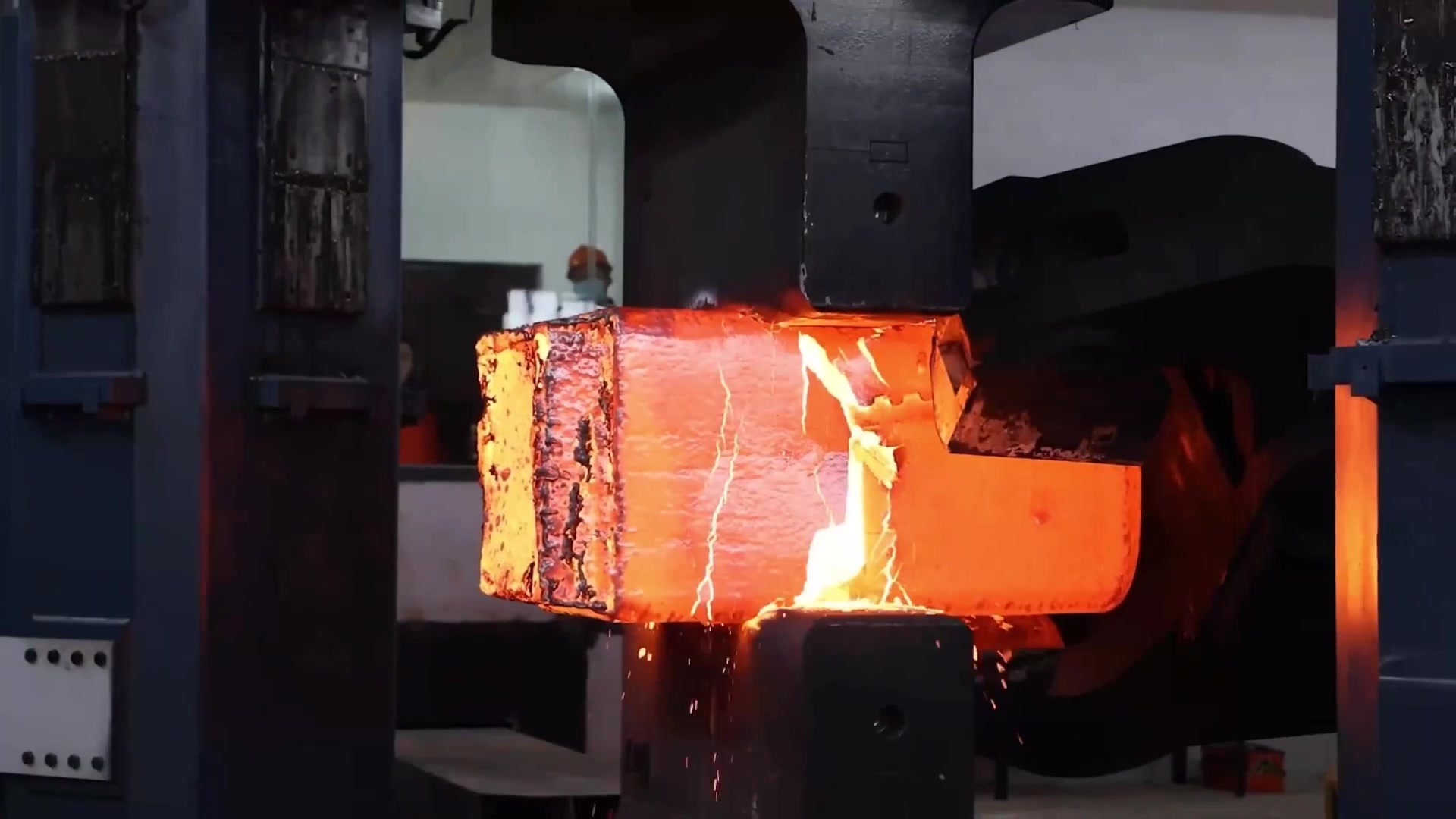

What improvements should be made in the production process of forgings?

The production process of forgings is a complex process involving multiple stages. To ensure product quality and production efficiency, a series of improvements are necessary.

The production process of forging parts is a complex process involving multiple stages. To ensure product quality and production efficiency, a series of improvements are necessary. The following are some possible directions for improvement:

I. Process Optimization

1. Optimize the forging process. Through reasonable heat treatment and cooling schemes, improve the plasticity and toughness of the metal, and improve the quality of the forgings.

2. Introduce advanced numerical simulation technology to simulate the metal flow and deformation during the forging process, optimize the mold design, and reduce the defect rate.

II. Equipment Upgrades

1. Update outdated forging equipment and introduce high-precision and high-efficiency modern equipment to improve production efficiency and product quality.

2. Adopt automation and intelligent technologies to achieve automated control of the production process and reduce errors caused by manual operation.

III. Material Management

1. Establish a strict material inspection system to ensure that the quality of incoming materials meets the requirements.

2. Test the properties of different materials and select suitable materials for production to improve product performance and service life.

IV. Quality Control

1. Strengthen quality inspection during the production process, monitor key processes in real time, and ensure stable product quality.

2. Introduce advanced quality inspection equipment and methods to improve inspection accuracy and efficiency.

V. Production Management

1. Introduce modern production management concepts and models, such as lean production and intelligent manufacturing, to improve production efficiency and resource utilization.

2. Strengthen employee training and skill improvement to improve employee quality and enhance quality control awareness during the production process.

VI. Environmental Protection and Energy Saving

1. Optimize production processes and equipment to reduce energy consumption and waste emissions during production and achieve green production.

2. Introduce renewable energy and environmentally friendly materials to reduce the environmental impact of the production process.

VII. Summary

The improvement of the forging production process is a systematic project that needs to be comprehensively considered from multiple aspects such as process, equipment, materials, quality, management, and environmental protection. Through continuous improvement and innovation, production efficiency, product quality, and competitiveness can be improved, and the sustainable development of the enterprise can be achieved.

Jinbo Forging Dingxiang Flange

Previous

Previous

Related information

2025-04-03

Introduction to flange pipe plate, come and collect it!

Flange plates, as important connecting pieces, are widely used in various piping systems.

2025-04-03

Manufacturing process of spindle forging

Spindle forgings are one of the key components in mechanical equipment, and their manufacturing process requires strict procedures to ensure quality.

2025-04-03

Types and Applications of Flanges

A flange is a connecting device widely used in the connection of various pipes, containers, valves, and other equipment.

2025-04-03

Working principle of carbon steel flanges

Carbon steel flanges are connecting devices widely used in piping systems and other industrial fields. Their working principle is based on mechanical connection and sealing principles, ensuring efficient and safe system operation.

2025-04-03

What improvements should be made in the production process of forgings?

The production process of forgings is a complex process involving multiple stages. To ensure product quality and production efficiency, a series of improvements are necessary.

2025-04-03

What is the cold bending process flow?

Cold bending is a metal sheet bending process widely used in construction, machinery, transportation and other fields.