03

2025

-

04

Manufacturing process of spindle forging

Spindle forgings are one of the key components in mechanical equipment, and their manufacturing process requires strict procedures to ensure quality.

Spindle forgings are one of the key components in mechanical equipment, and their manufacturing process requires strict procedures to ensure quality. The following are the manufacturing steps for spindle forgings:

1. Raw Material Preparation

First, high-quality steel is selected as the raw material. After passing quality inspection, surface cleaning and preparation for cutting are carried out.

2. Cutting

According to the size and weight requirements of the forging, cutting equipment is used to cut the raw material into suitable billets.

3. Heating

The cut steel is heated to the forging temperature according to the type of material and the requirements of the forging.

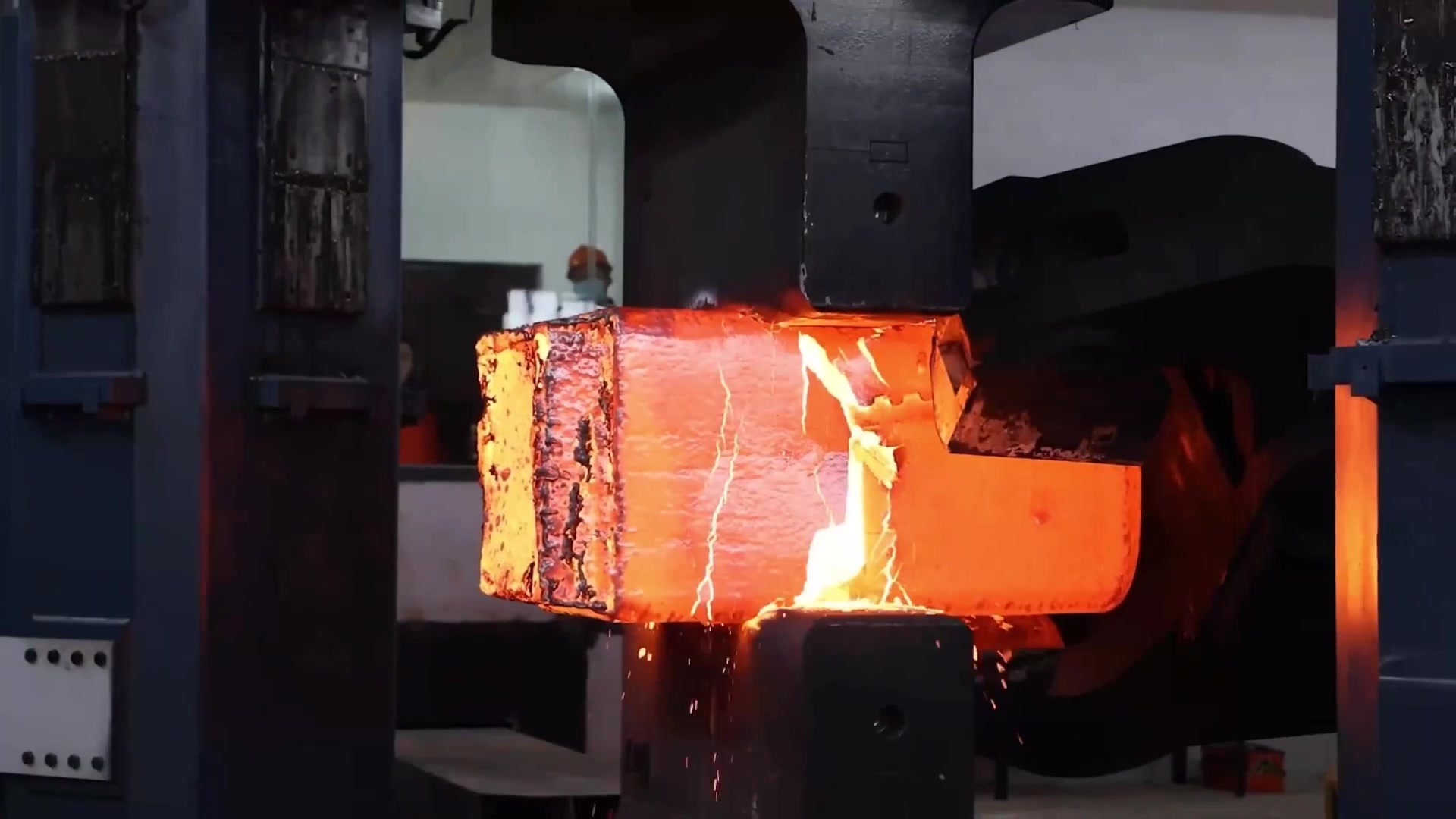

4. Forging

The steel is repeatedly forged on forging equipment to change its shape and internal structure, achieving the required spindle shape. During the forging process, temperature, pressure, and deformation must be strictly controlled.

5. Heat Treatment

After forging, heat treatment is carried out, including normalizing, annealing, quenching, and tempering, to improve the hardness, performance, and wear resistance of the spindle forging.

6. Flaw Detection

Non-destructive testing equipment, such as ultrasonic testing and magnetic particle testing, is used to inspect the spindle forging for internal and external defects to ensure that its quality meets the requirements.

7. Machining

The forged and heat-treated spindle forging is machined, including turning, milling, and drilling, to achieve precise dimensions and shape.

8. Assembly and Testing

The finished spindle forging is assembled, and then performance tests, such as hydrostatic tests and fatigue tests, are conducted to verify its performance in actual use.

9. Painting and Packaging

After passing the test, the spindle forging is surface painted to improve its corrosion resistance and aesthetics. Then, it is packaged for storage and transportation.

10. Quality Inspection and Warehousing

Finally, the spindle forging undergoes final quality inspection to ensure that it meets the design requirements and quality standards. After passing inspection, it is managed in the warehouse for future use.

In summary, the manufacturing process of spindle forgings includes raw material preparation, cutting, heating, forging, heat treatment, flaw detection, machining, assembly and testing, painting and packaging, and quality inspection and warehousing. These steps must be strictly followed to ensure the quality and performance of the spindle forging.

Jinbo Forging Dingxiang Flange

Related information

2025-04-03

Introduction to flange pipe plate, come and collect it!

Flange plates, as important connecting pieces, are widely used in various piping systems.

2025-04-03

Manufacturing process of spindle forging

Spindle forgings are one of the key components in mechanical equipment, and their manufacturing process requires strict procedures to ensure quality.

2025-04-03

Types and Applications of Flanges

A flange is a connecting device widely used in the connection of various pipes, containers, valves, and other equipment.

2025-04-03

Working principle of carbon steel flanges

Carbon steel flanges are connecting devices widely used in piping systems and other industrial fields. Their working principle is based on mechanical connection and sealing principles, ensuring efficient and safe system operation.

2025-04-03

What improvements should be made in the production process of forgings?

The production process of forgings is a complex process involving multiple stages. To ensure product quality and production efficiency, a series of improvements are necessary.

2025-04-03

What is the cold bending process flow?

Cold bending is a metal sheet bending process widely used in construction, machinery, transportation and other fields.