03

2025

-

04

What are the causes of flange rust and rust prevention failure?

Flange rusting is mainly due to chemical reactions with oxygen, moisture, and other chemical elements in the atmospheric environment.

I. Reasons for Flange Rust

Flange rusting is mainly due to chemical reactions with oxygen, moisture, and other chemical elements in the atmosphere. Specific factors include:

1. Humidity and Moisture: High humidity or moisture retained on the flange surface accelerates the electrochemical process of iron oxidation, forming rust.

2. Oxygen Contact: When metal comes into contact with oxygen, an oxidation reaction occurs, producing oxides.

3. Atmospheric Pollutants: Contact between pollutants such as sulfur dioxide and hydrogen sulfide with the metal surface creates a corrosive environment.

4. Microbial Erosion: Certain microorganisms in some environments can also promote corrosion reactions.

5. Temperature Changes: These lead to alternating cycles of moisture condensation and drying on the metal surface, intensifying the corrosion process.

II. Reasons for Rust Prevention Failure

Flange rust prevention failure can stem from several aspects, including:

1. Improper Material Selection: Failure to choose suitable metal materials based on the operating environment; some metal materials are more prone to rust.

2. Insufficient Surface Treatment: Oil stains, impurities, etc., on the metal surface are not cleaned thoroughly, affecting the bonding between the rust-proof coating and the substrate.

3. Coating Quality Issues: Poor coating quality, insufficient thickness, or improper coating process prevents effective isolation of the metal from corrosive media in the environment.

4. Environmental Factors: Harsh environmental conditions such as high temperature, high humidity, and high salinity accelerate the aging or failure of the rust-proof coating.

5. Improper Maintenance: Long-term lack of necessary maintenance and inspection leads to coating damage or peeling that is not discovered and addressed promptly.

In response to the above reasons, corresponding measures should be taken to prevent flange rust and ensure successful rust prevention. For example, improve the working environment to reduce humidity, enhance ventilation to reduce the concentration of corrosive gases; select corrosion-resistant metal materials; improve surface treatment quality to ensure good bonding between the coating and the substrate; use high-quality rust-proof coatings and optimize the coating process; strengthen equipment maintenance and inspection, and promptly address coating damage, etc. In addition, develop a regular maintenance plan based on the characteristics of the operating environment, regularly inspect and maintain the flanges to ensure that they maintain a good working condition for a long time.

In summary, understanding the causes of flange rust and rust prevention failure is crucial for taking effective preventive measures. Through reasonable material selection, design, manufacturing, and maintenance management, the service life of the flange can be extended and maintenance costs can be reduced.

Jinbo Forging Dingxiang Flange

Related information

2025-04-03

Introduction to flange pipe plate, come and collect it!

Flange plates, as important connecting pieces, are widely used in various piping systems.

2025-04-03

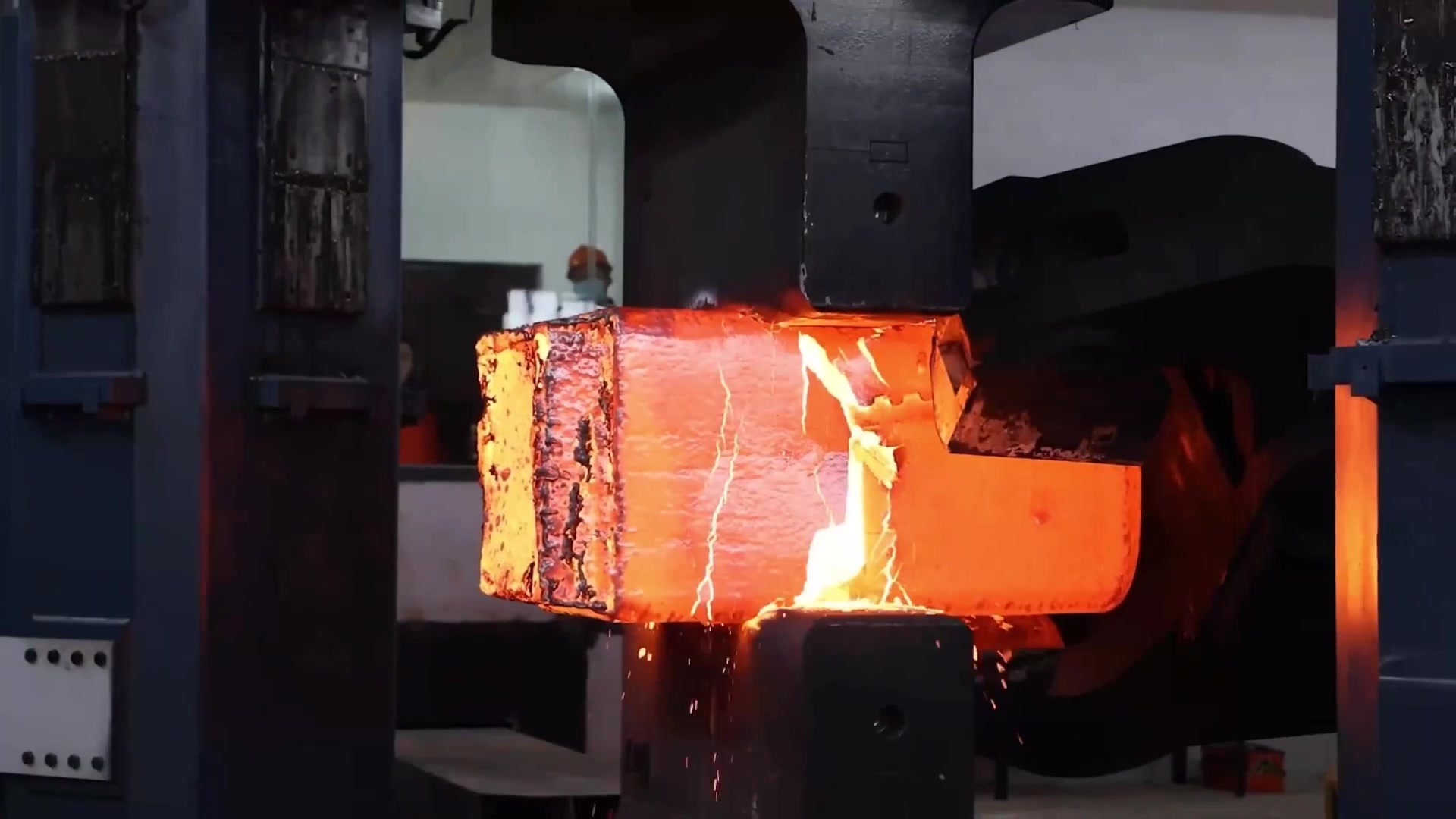

Manufacturing process of spindle forging

Spindle forgings are one of the key components in mechanical equipment, and their manufacturing process requires strict procedures to ensure quality.

2025-04-03

Types and Applications of Flanges

A flange is a connecting device widely used in the connection of various pipes, containers, valves, and other equipment.

2025-04-03

Working principle of carbon steel flanges

Carbon steel flanges are connecting devices widely used in piping systems and other industrial fields. Their working principle is based on mechanical connection and sealing principles, ensuring efficient and safe system operation.

2025-04-03

What improvements should be made in the production process of forgings?

The production process of forgings is a complex process involving multiple stages. To ensure product quality and production efficiency, a series of improvements are necessary.

2025-04-03

What is the cold bending process flow?

Cold bending is a metal sheet bending process widely used in construction, machinery, transportation and other fields.