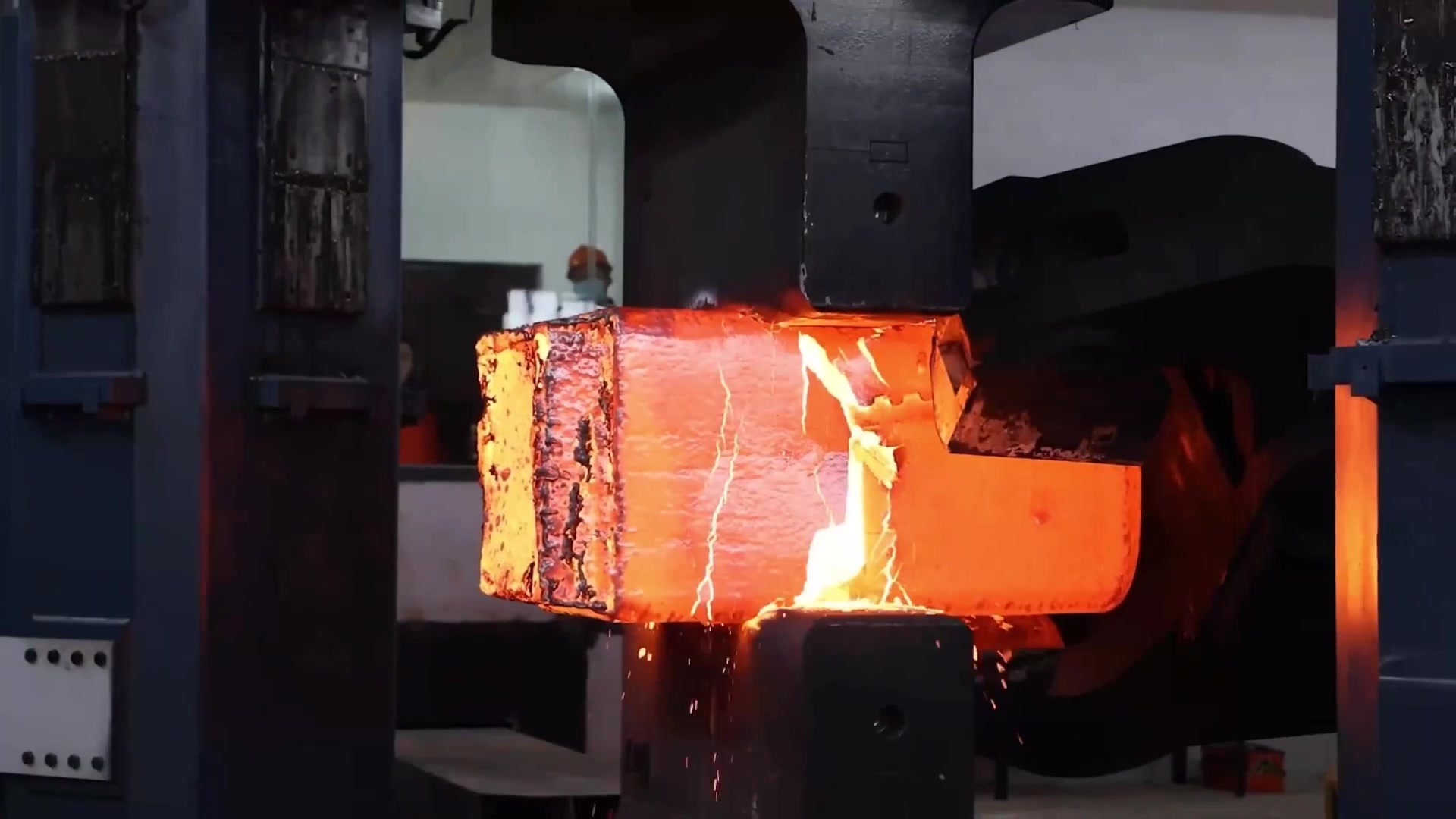

Large takeover forgings

Category:

Hotline:

Product description

Large forged pipe fittings are key components in industrial fields, widely used in petroleum, chemical, power, aerospace and other sectors. Their quality and performance directly impact the operational safety and efficiency of the entire equipment. Below, we will introduce large forged pipe fittings from aspects such as concept, application scenarios, development trends, performance evaluation, and purchasing suggestions.

I. Conceptual Analysis

Large forged pipe fittings are large metal components processed through forging, mainly used to connect pipelines or other equipment, bearing pressure, weight and stress. The materials are usually carbon steel, alloy steel, stainless steel, etc.

II. Application Scenarios

Large forged pipe fittings are widely used in key equipment in the petroleum, chemical, power, and aerospace industries, such as reactors, heat exchangers, boilers, and pipeline systems.

III. Development Trends

With the continuous advancement of industrial technology, large forged pipe fittings are developing towards high quality, high performance, and high reliability. At the same time, the demand for green environmental protection and energy saving and emission reduction is also promoting innovation and improvement of forging technology.

IV. Performance Evaluation

When evaluating the performance of large forged pipe fittings, the main considerations are material composition, forging process, microstructure, mechanical properties, and corrosion resistance. In addition, attention should be paid to its appearance quality, dimensional accuracy, and surface roughness.

V. Purchasing Suggestions

When purchasing large forged pipe fittings, first choose a reputable supplier to ensure product quality. Second, choose the appropriate specifications, materials, and performance according to actual needs. Finally, pay attention to checking the product qualification certificates and test reports and other quality certification documents.

VI. Summary

Large forged pipe fittings are important components in the industrial field, and their quality and performance have an important impact on the operational safety and efficiency of equipment. During the purchase and use process, you should fully understand its concept, application scenarios, development trends, and performance evaluation to ensure that you purchase the appropriate product. During use, regular maintenance and inspection should also be carried out to ensure its normal operation and extend its service life.

Flange

Jinbo

Previous

Next

Previous

Next

Other products

I want to consult