Ring forging

Category:

Hotline:

Product description

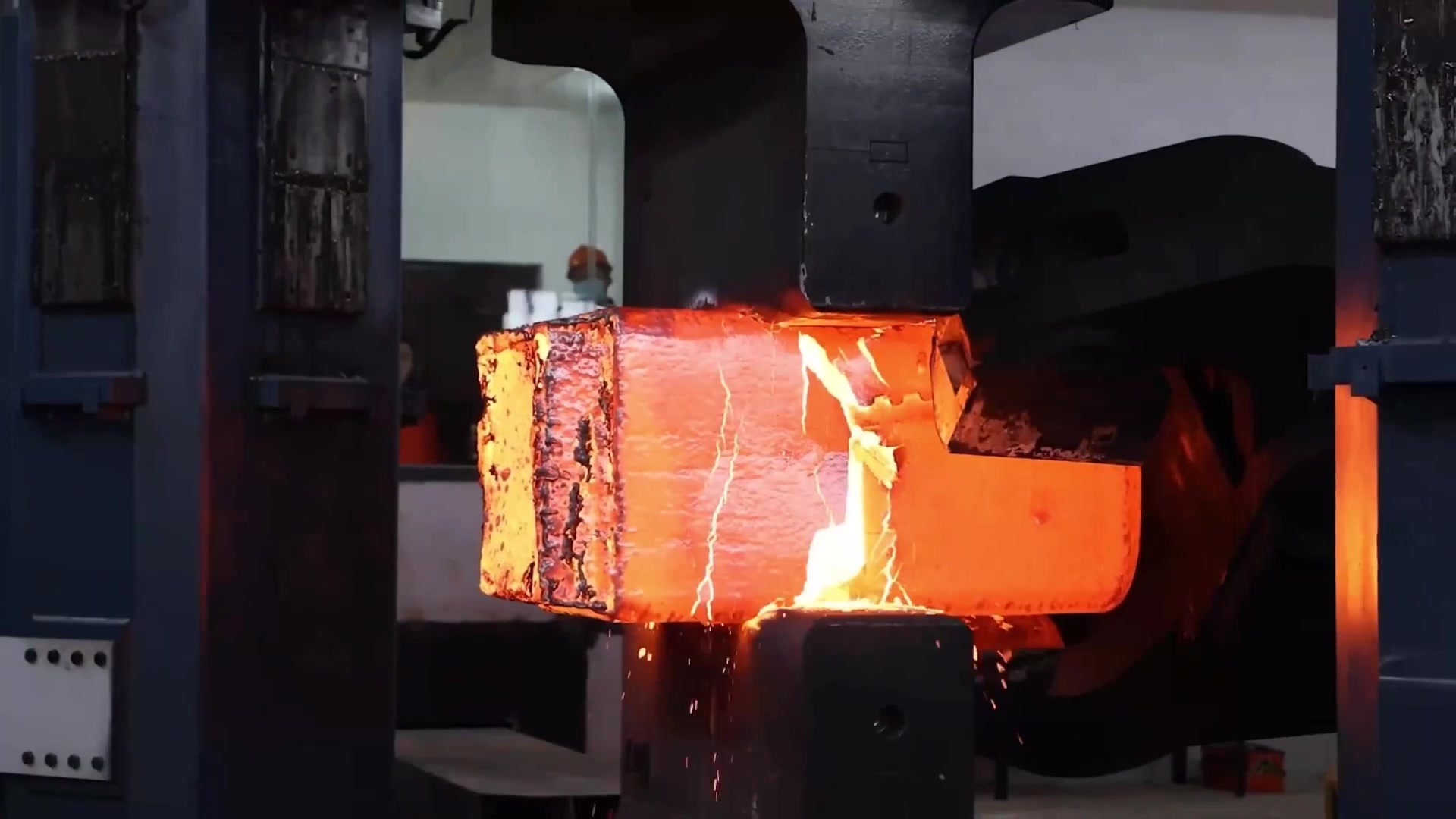

Ring forgings are important mechanical parts widely used in aviation, automotive, energy, and shipbuilding industries. Their main function is to provide high strength, toughness, and excellent wear resistance through a forging process to meet the safe operation requirements of various mechanical equipment.

I. Overview of Ring Forgings

Ring forgings are usually made of metal materials through hot forging, with a continuous and uniform metal fiber structure. Their shape is ring-shaped, and different sizes and thicknesses can be customized according to actual needs. Ring forgings have characteristics such as high strength, high rigidity, high wear resistance, and high fatigue life, making them indispensable key components in mechanical equipment.

II. Importance of Ring Forgings

In the aviation and automotive industries, ring forgings withstand various complex mechanical properties and working environments, such as high temperature, high pressure, and strong corrosion. Therefore, the quality and performance of ring forgings are crucial to the safe operation and reliability of mechanical equipment. High-quality ring forgings can ensure the long-term stable operation of mechanical equipment, improving overall performance and service life.

III. Applications of Ring Forgings

Ring forgings are widely used in key components of aero-engines such as turbines, gears, and shafts; important parts of automotive transmission, suspension, and braking systems; and various structural and connecting parts in the energy and shipbuilding industries. With the continuous development of industrial technology, the application fields of ring forgings will become increasingly extensive.

IV. Advantages of Ring Forgings

Compared to other metal parts, ring forgings have the following advantages:

1. High Performance: Ring forgings have characteristics such as high strength, high rigidity, high wear resistance, and high fatigue life, meeting the needs of various complex working conditions.

2. Safety: The quality and performance of ring forgings are stable, ensuring the safe operation of mechanical equipment.

3. Applicability: Ring forgings can be customized in different sizes and thicknesses to adapt to the needs of different mechanical equipment.

In summary, ring forgings are important mechanical parts with broad application prospects. With the continuous development of industrial technology, the performance and quality of ring forgings will continue to improve, providing better guarantees for the safe operation and reliability of various mechanical equipment.

Other products

I want to consult