Ball valve body

Category:

Hotline:

Product description

I. Overview

The ball valve body is a key component of the ball valve, mainly used to control the opening and closing of fluids. It is widely used in petroleum, chemical, metallurgical, power, and water treatment industries.

II. Structure and Material

1. Structure: The ball valve body mainly consists of the valve body, ball, seat, stem, and sealing elements. Among them, the valve body is the "skeleton" of the ball valve, supporting the entire ball and its accessories, ensuring the normal operation of the ball valve.

2. Material: The selection of the material for the ball valve body is crucial and needs to be chosen based on the usage environment and medium properties. Common materials include cast iron, carbon steel, stainless steel, and alloy steel.

III. Manufacturing Process

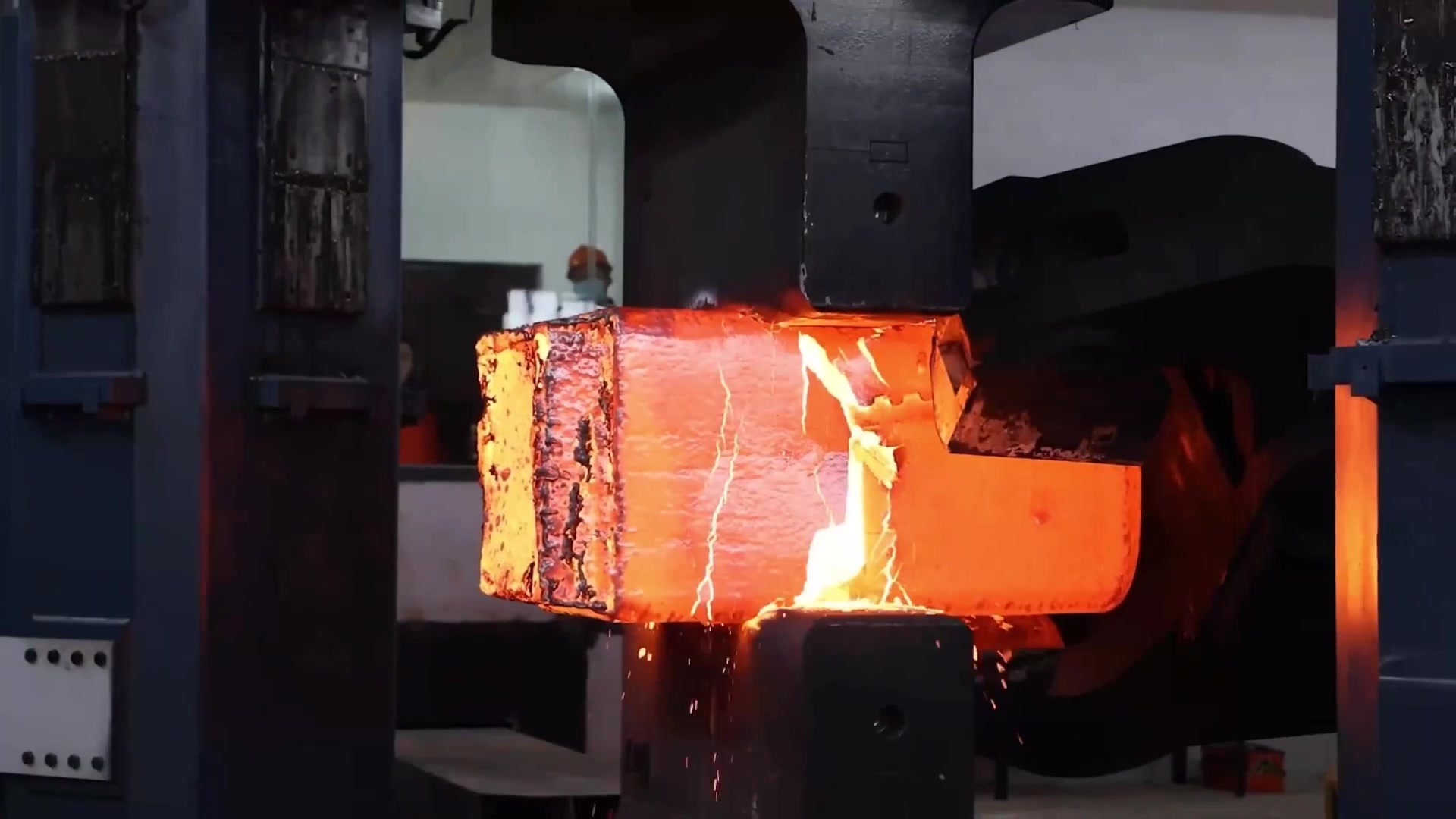

The manufacturing process of the ball valve body includes casting, machining, and heat treatment. Casting is the main method for producing ball valve bodies with complex shapes; machining ensures the precision and surface quality of the valve body; and heat treatment improves the mechanical properties and corrosion resistance of the valve body.

IV. Characteristics

1. Low fluid resistance: Because the ball body channel of the ball valve is straight-through, the fluid resistance is relatively small when it passes through.

2. Good sealing performance: The ball valve uses elastic sealing or metal sealing, ensuring good sealing performance.

3. Rapid switching: The ball valve has a small switching torque and is easy to achieve rapid switching.

4. Wide range of applications: Ball valves can be used for various media and working environments, such as gases, liquids, high temperatures, and high pressures.

V. Types and Applications

According to the different valve body structures, ball valves can be divided into floating ball valves, fixed ball valves, and elastic ball valves. They are widely used in petroleum, chemical, metallurgical, and power industries, such as pipeline control and fluid regulation.

VI. Maintenance and Upkeep

To ensure the long-term stable operation of the ball valve, regular maintenance and upkeep of the ball valve body are required. This includes regularly checking the sealing elements, cleaning the inside of the valve body, and checking fasteners. Damaged or worn parts should be replaced in time.

VII. Development Trends

With the continuous development of industrial technology, ball valve bodies are developing towards high performance and intelligence. In the future, ball valves will pay more attention to environmental protection and energy saving, while achieving more precise remote control.

In summary, the ball valve body, as the core component of the ball valve, its performance and quality directly affect the performance and service life of the entire ball valve. Therefore, it is crucial to choose a high-quality ball valve body.

Other products

I want to consult